Transporting hazardous materials across highways requires a high level of responsibility, awareness, and adherence to strict safety standards. The U.S. Department of Transportation (DOT) outlines specific requirements in 49 CFR Part 397, which governs the transportation of hazardous materials by motor carriers. These rules are designed to ensure public safety, environmental protection, and operational integrity within the trucking industry.

In this comprehensive guide, we will explore the key elements of Hazmat DOT Compliance, including training requirements, placarding standards, driver qualification, and recordkeeping essentials every fleet must understand.

Understanding Hazmat DOT Compliance and 49 CFR Part 397

Hazmat DOT Compliance refers to the set of federal regulations that govern how hazardous materials are transported by commercial vehicles. The regulations are primarily found in Title 49, Code of Federal Regulations (CFR), Parts 171–180, with Part 397 focusing on motor carrier responsibilities, driver conduct, and routing of hazardous materials.

Part 397 specifies operational rules that apply to all motor carriers and drivers transporting hazardous materials on public highways. These include requirements for safe parking, attendance of vehicles, routing restrictions, and adherence to local and federal safety standards.

Compliance with these regulations is crucial because violations can lead to serious legal penalties, environmental damage, and life-threatening accidents. For carriers, maintaining a strong compliance framework not only ensures safety but also builds trust with clients and regulatory authorities.

What Are Hazardous Materials (Hazmat)?

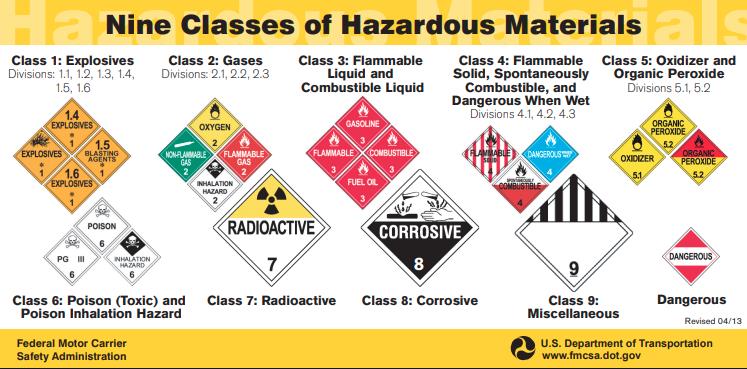

Hazardous materials are substances that pose a risk to health, safety, or the environment during transportation. The DOT classifies them into nine categories: explosives, gases, flammable liquids, flammable solids, oxidizers, toxic substances, radioactive materials, corrosives, and miscellaneous dangerous goods.

Each category has its own handling and labeling requirements. For example, flammable liquids like gasoline must be transported in specific containers and clearly labeled with the appropriate hazmat placards.

Carriers must identify the materials being transported, classify them correctly, and follow packaging, marking, and labeling requirements before they reach public highways. Misclassification or mislabeling of hazardous materials is one of the most common causes of DOT citations and fines.

DOT Hazmat Regulations: The Core Framework

The foundation of DOT hazmat regulations lies in 49 CFR Parts 171–180, with Part 397 focusing specifically on highway transportation. Some of the key areas include:

- Part 171–173: General information, classification, and packaging requirements.

- Part 174–177: Transportation regulations for rail, air, vessel, and highway.

- Part 178–180: Specifications for packaging, testing, and maintenance.

Under Part 397, specific requirements for carriers include:

- Ensuring the driver holds the proper Hazardous Materials Endorsement (HME) on their CDL.

- Complying with vehicle parking and attendance rules when carrying hazardous materials.

- Following designated routes approved for hazmat transport.

- Maintaining proper documentation such as shipping papers and emergency response information.

Failure to comply with these rules can result in substantial fines or loss of operating authority.

DOT Hazmat Training Requirements (49 CFR 172.704)

One of the most essential components of hazmat compliance is proper employee training. According to 49 CFR 172.704, all hazmat employees must undergo training in four critical areas:

- General Awareness/Familiarization: Provides basic knowledge of hazmat regulations.

- Function-Specific Training: Focuses on tasks directly related to the employee’s job, such as loading, marking, or documentation.

- Safety Training: Covers emergency response procedures and protective measures.

- Security Awareness Training: Ensures employees can recognize and respond to security threats.

Training must be completed within 90 days of employment and repeated every three years. Employers must maintain written records of training completion, including the employee’s name, training date, description, and the trainer’s details.

Investing in ongoing training not only ensures compliance but also reduces risks and enhances operational safety.

Hazmat Placards and Labeling Requirements

Proper labeling and placarding are among the most visible aspects of hazmat compliance. Placards help emergency responders identify the type of material being transported in case of an accident.

DOT requires that vehicles carrying hazardous materials display the correct placards on all four sides of the transport unit. The placard must include:

- The hazard class number (1–9).

- The appropriate color code and symbol.

- The UN identification number, if applicable.

Source: https://www.fmcsa.dot.gov/sites/fmcsa.dot.gov/files/docs/Nine_Classes_of_Hazardous_Materials-4-2013_508CLN.pdf

For example, a truck carrying flammable liquids must display a red placard with a flame symbol and hazard class “3.”

Failure to use correct placards or damaged signs can lead to significant DOT violations. Regular inspection of placards, including their visibility and legibility, should be part of every carrier’s pre-trip checklist.

DOC: Nine Classes of Hazardous Materials

Driver Qualification for Hazmat Transport

Drivers play a crucial role in ensuring hazmat safety. According to FMCSA regulations, any driver transporting hazardous materials requiring placards must hold a Commercial Driver’s License (CDL) with a Hazmat Endorsement (HME).

Obtaining this endorsement requires:

- Passing a Transportation Security Administration (TSA) background check.

- Completing written knowledge tests on hazmat safety and regulations.

- Meeting medical and driving history requirements.

In addition to licensing, carriers must maintain Driver Qualification Files (DQFs) that include:

- Employment application.

- Motor Vehicle Record (MVR).

- Medical examiner’s certificate.

- Road test and training records.

SafeRoad Compliance assists carriers in maintaining up-to-date DQ files and ensuring each driver meets federal safety and qualification standards.

Vehicle Requirements and Inspections

Vehicles used for hazardous materials transportation must meet specific DOT standards. This includes proper cargo securement, tank integrity, and inspection compliance under 49 CFR Part 396.

Regular inspections are critical to ensure the vehicle is safe for operation. Key elements include:

- Checking brake systems, tires, and emergency equipment.

- Verifying that all valves and closures are properly sealed.

- Ensuring fire extinguishers and spill containment tools are accessible.

The Driver Vehicle Inspection Report (DVIR) plays a central role in daily safety verification. Carriers must keep these reports on file and ensure prompt corrective action for any defects identified.

Routing, Parking, and Attendance Rules under Part 397

Part 397 includes detailed guidance on how and where hazardous materials can be transported. These routing rules are designed to minimize public exposure to risk.

- Routing: Drivers must follow designated hazmat routes approved by state or local authorities. Deviating from these routes without authorization is a violation.

- Parking: Vehicles carrying hazardous materials cannot be parked near open flames, populated areas, or public gatherings.

- Attendance: A qualified driver must attend the vehicle at all times when parked with certain hazardous materials, ensuring immediate response if an emergency arises.

Carriers should develop routing plans in compliance with federal and local regulations and communicate them clearly to all drivers.

Recordkeeping and Documentation Requirements

Accurate documentation is vital to maintaining compliance. Carriers must keep detailed records of:

- Hazmat employee training (as per 49 CFR 172.704).

- Shipping papers and emergency response information.

- Vehicle inspection and maintenance logs.

- Driver qualification and medical records.

These records must be organized and easily accessible during DOT audits. Maintaining proper documentation not only protects carriers from penalties but also demonstrates a culture of safety and transparency.

The Role of Technology in Hazmat Compliance

Modern fleet management technology plays a significant role in enhancing hazmat safety. IoT-based systems and ELDs (Electronic Logging Devices) help carriers track vehicle locations, monitor driver behavior, and ensure route compliance.

Advanced compliance software can automate documentation, schedule training reminders, and generate digital records for audits. Integrating technology into compliance management allows carriers to minimize errors, reduce paperwork, and improve real-time safety monitoring.

Why Hazmat DOT Compliance Matters

Ensuring compliance with hazmat regulations protects not only the carrier but also the public and the environment. Violations can lead to severe fines, loss of operating authority, and reputational damage.

Compliance also improves operational efficiency, as well-trained drivers and properly maintained vehicles experience fewer delays and accidents. Moreover, carriers that maintain strong safety records often benefit from better CSA scores and more business opportunities.

Key Takeaways

- DOT Hazmat Compliance is governed under 49 CFR Parts 171–180, with Part 397 focusing on highway safety and routing.

- Hazmat employees must complete training every three years as per 49 CFR 172.704.

- Vehicles must display proper hazmat placards and follow designated routes.

- Carriers must maintain updated DQ files, inspection reports, and training records.

FAQs

DOT Hazmat Compliance refers to federal regulations that govern the safe transportation of hazardous materials by commercial vehicles, ensuring safety and environmental protection.

Any employee involved in handling, loading, shipping, or transporting hazardous materials must complete hazmat training as outlined in 49 CFR 172.704.

Hazmat training must be renewed every three years, or sooner if regulations or job functions change.

Placards are diamond-shaped signs displayed on vehicles transporting hazardous materials to identify the hazard class and type of material being carried.

Penalties can include heavy fines, suspension of operating authority, and even criminal charges for willful violations.